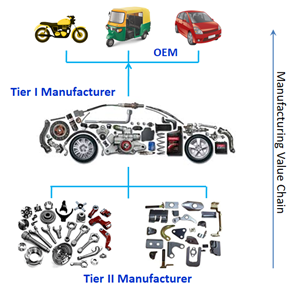

World’s 3rd largest motorcycle manufacturer and largest 3 wheeler manufacturer and exporting 2/3 wheelers to 70 countries

globally.

BAL have achieved a completely paperless collaboration between BAL, their Tier I and Tier II suppliers for concern

resolution management, child parts incoming inspection with online PDI submission by component manufacturers, PPM tracking of

suppliers, Supplier audit process and compliance management and New products development.

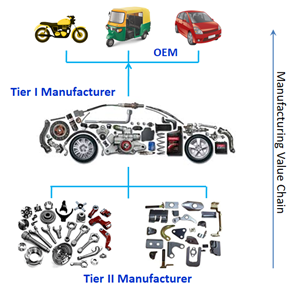

RIYO software suite deployed at

300 + Tier II SME component manufacturers helps them by creating a framework of operations management for Quality, Productivity

and Maintenance management adhering to international standards and practices.

T1 automotive assemblies manufacturing companies collaborate with customers on one side and component manufacturers on other side,

hence have huge collaboration requirements with multiple stake holders.

Collaborating with suppliers for supplier quality improvement

and supplier improvement was a challenge. Achieved a completely paperless collaboration with suppliers for incoming child part inspection,

supplier PPM tracking, new products development and day to day coordination relating to concerns, their analysis and resolution with continuous

improvement activities.

Transformed the activities from reactive to proactive for supplier excellence resulting in improvement of parts quality,

reduced coordination efforts with real time data availability and visibility.

At the lower level of automotive value chain they need to take up digitization of processes, data availability, data visibility

and data analytics with deployment of affordable emerging technologies to stay competitive in emerging digital manufacturing

ecosystem.

RIYO software suite of OpExWorks provides for digitization of processes relating to Quality Management, Productivity

Management and Maintenance management for MSME manufacturing companies. Designed and Developed considering the issues and

challenges faced by MSME manufacturers, RIYO platform has enabled affordable technology adoption in several MSME manufacturing

companies.

These are just representative transformation stories out of several. Connect with us to know the solution best suitable to your specific scenario for futuristic business transformation. Start your transformation journey with us.